Auto Steering | Inspection Triangle Part 3

This blog series delves into why many auto shops and technicians believe in the Auto Inspection Triangle concept. An Auto Inspection Triangle focuses on three aspects of your vehicle that work together: Stability, Steering, and Stopping. In part 3, Auto Steering, we will discuss how your vehicle’s Power Steering, Steering System, and Suspension System contribute to the Auto Inspection Triangle.

This blog series delves into why many auto shops and technicians believe in the Auto Inspection Triangle concept. An Auto Inspection Triangle focuses on three aspects of your vehicle that work together: Stability, Steering, and Stopping. In part 3, Auto Steering, we will discuss how your vehicle’s Power Steering, Steering System, and Suspension System contribute to the Auto Inspection Triangle.

What is Auto Steering?

The auto steering system allows the driver to steer the vehicle by converting the movement of the steering wheel to a corresponding movement of the wheels & tires. The system’s interconnected parts are as follows: Steering wheel to steering column to the suspension system through a system of pivoted joints. This series of connections allows the vehicle’s wheels to move up & down over the road without changing the angle of the steering wheel. In addition, this system ensures that the tires move appropriately when cornering.

Steering Components

The two steering systems in use today are the conventional Steering Box and the Rack & Pinion. Either method may be ‘power-assisted’ for easier steering, even when moving at slow speeds or over especially rough terrain.

Steering Box

Manufacturers still use the conventional Steering Box on some newer trucks and SUVs but it is more common on older model vehicles. A gear mechanism connects the vehicle’s steering column base to the front axle. There is a ‘worm-gear’ inside a box at the bottom of the steering column. A ‘worm-gear’ is a threaded cylinder, which is similar to a short bolt. The worm-gear engages the nut, peg, or sector, moving it through a recirculating-ball system. When a motorist turns the steering wheel, the worm-gear moves a series of interconnected arms and rods which work together to pivot the front wheels.

Manufacturers still use the conventional Steering Box on some newer trucks and SUVs but it is more common on older model vehicles. A gear mechanism connects the vehicle’s steering column base to the front axle. There is a ‘worm-gear’ inside a box at the bottom of the steering column. A ‘worm-gear’ is a threaded cylinder, which is similar to a short bolt. The worm-gear engages the nut, peg, or sector, moving it through a recirculating-ball system. When a motorist turns the steering wheel, the worm-gear moves a series of interconnected arms and rods which work together to pivot the front wheels.

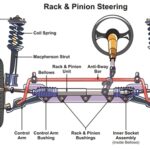

Rack & Pinion

The Rack & Pinion design transfers spinning motion into straight, direct motion. It’s made up of a toothed gear (pinion) and a long-toothed bar (rack). The pinion is located at the base of the steering column and turns along with your steering wheel. The steering rack is located inside a metal tube attached to the chassis. When the pinion turns, it connects with the toothed steering rack, forcing the rack to move to the right or left. Your vehicle’s wheels will turn according to the rack’s movement.

Tie rod ends and steering knuckles complete the connection between the steering rack and the front wheels. The tie rod ends flexibility allow for up and down movement, such as driving over bumps or holes.

In a power assisted rack & pinion system, a rack tube, containing a power steering cylinder attaches to the steering rack. An engine-powered pump delivers pressurized power steering fluid to the rotary valve on the pinion gear. When you turn the steering wheel, the rotary valve directs pressurized fluid to one side of the piston. This easily moves the steering rack laterally within the metal tube, which then turns the front tires in the desired direction.

Power Steering

Power steering assists a driver by reducing the amount of power or force needed to steer the vehicle. All modern automobiles come equipped with a power steering system. A power steering system operates with a hydraulic piston and motor powered by the vehicle’s engine. Power steering facilitates easy direction changes with just small steering wheel adjustments. Fortunately, power steering is a breeze compared to the older manual steering systems.

Suspension System

The suspension system plays a vital role in your vehicle’s safety and performance. Modern vehicle suspension systems must support the vehicle, deliver reliable steering, and provide optimum traction in various road conditions. While the suspension system works independently, it also works together with the steering system. What if your vehicle has worn or damaged suspension components? In that case, it can contribute to the wear and failure of other parts in your vehicle.

Troubleshoot Auto Steering Issues

Auto Steering components can suffer from several issues. Here are some common issues with both steering systems and the possible causes:

- Grinding noises: Check for low power-steering fluid levels and inspect the lubricant in the suspension.

- Squealing noises: Check for a damaged power steering belt.

- Leaks in the Rack & Pinion hydraulic system: Check the O-ring seals, rack tube ends, and power steering hoses.

- Leaks in the Steering Box: Check the worm gear shaft, the sector shaft seals, and the sector shaft cover.

- Loose Steering Wheel: May indicate worn rack & pinion gears, worn steering box, damaged steering mount bushings, or a faulty rotary valve.

- The steering feels stiff, or the steering wheel is hard to turn: Inspect the power steering fluid level; it may be low.

- Replace a torn rack & pinion bellows (or boot) to prevent dirt and debris from entering the rack and destroying the seal.

Service Intervals

Scheduling regular service inspections of your vehicle’s steering and suspension systems is a part of routine maintenance. Always follow the manufacturer’s recommended service intervals for your automobile. Look in your owner’s manual for the factory recommended service intervals. Expect to service the steering & suspension systems every 30,000 to 50,000-miles. You can also discuss with your service technician if the following conditions require a steering & suspension service:

- During your yearly routine maintenance service.

- When you get your tires replaced, balanced, or aligned.

- When you get your brakes serviced.

- If you are involved in an auto collision.

- If you notice any changes in the ride quality, handling, or stability of your vehicle.

Auto Steering Inspection in Midland, MI

We offer complete automotive services for foreign & domestic automobiles at All A’s Automotive & Transmission Repair in Midland, MI. Call us when your vehicle needs a diagnostic service to improve auto steering or address safety issues with your tires and suspension. Our experienced technicians will work hard to find the right solution for your needs.

Schedule Service

Ask your service technician about the Auto Inspection Triangle each time you bring your vehicle into All A’s Automotive & Transmission Repairs for tires, brakes, suspension, or steering services. Call us at (989) 631-4672 or visit our website to make your appointment online.

Previous Blog – Inspection Triangle: Auto Stability Part 2

Read Part 2 of this series; we discussed how your vehicle’s tires, tread, and suspension system contribute to Auto Stability. We also explored how to troubleshoot tire tread wear and offered maintenance suggestions.

Next Blog – Inspection Triangle: Auto Stopping Part 4

In part 4 of this blog series, we will focus on Stopping – the final leg of the Auto Inspection Triangle.

Posted in: Steering System, Suspension System

Leave a Comment (0) ↓